Let’s talk about the functionality of BioCloner – another part in the series about the practical features of our technology.

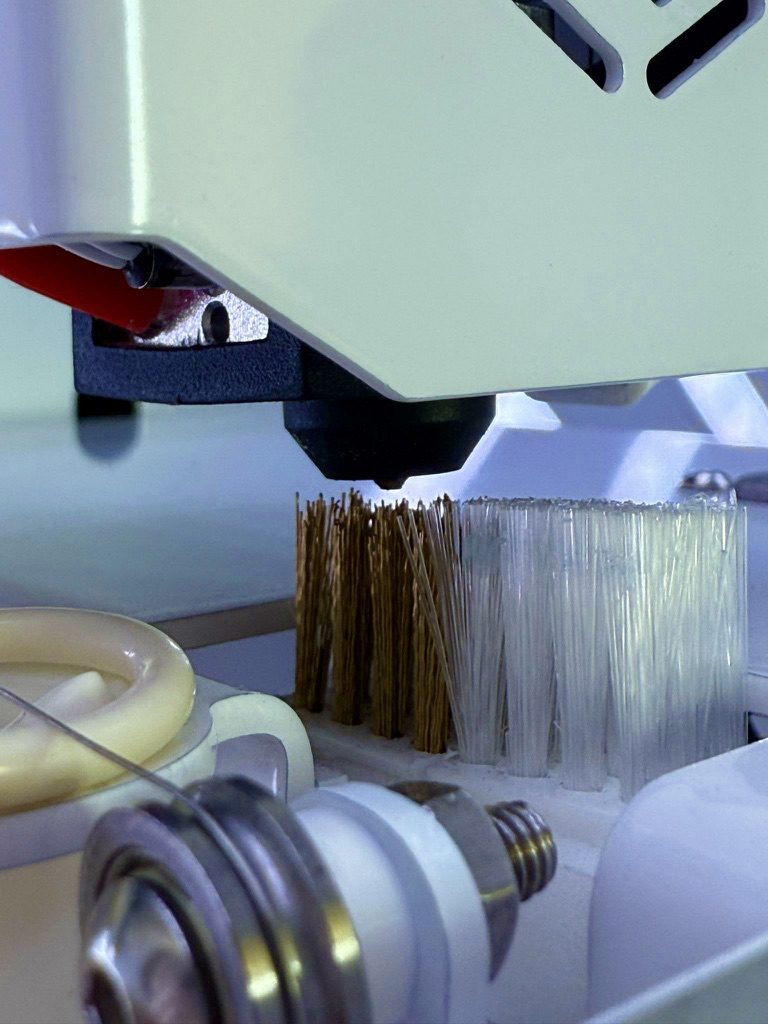

Cleaning Tool – a small component located next to the printbed in the BioCloner Desktop Pro machine.

What makes it so useful?

- It ensures print quality – as the name suggests, it cleans the nozzle tip from which the material is extruded during printing. This allows the substance to be applied precisely and evenly.

- It automates the entire cleaning process – the machine user does not need to clean the nozzle manually because the implemented technology allows the cleaning to be performed automatically at any point during printing. Nozzle cleaning is initiated directly from the software using a dedicated macro (command), ensuring convenience and full control over the process.

What does the cleaning process look like?

This process is performed in two modes: full and shorten.

Full mode – the printhead moves across the cutting filament, removing leftover material, and then cleans the nozzle with bristles.

Short mode skips the filament step and goes directly to cleaning the nozzle with bristles, which is sufficient to remove minor debris during continuous operation.

The cleaning tool includes a brush that comes in two variants: a soft brush for cleaning plastic nozzles and a hard brush designed for metal nozzles.

This is a proven feature, and in BioCloner it works even more precisely – an essential support for high-quality printing.