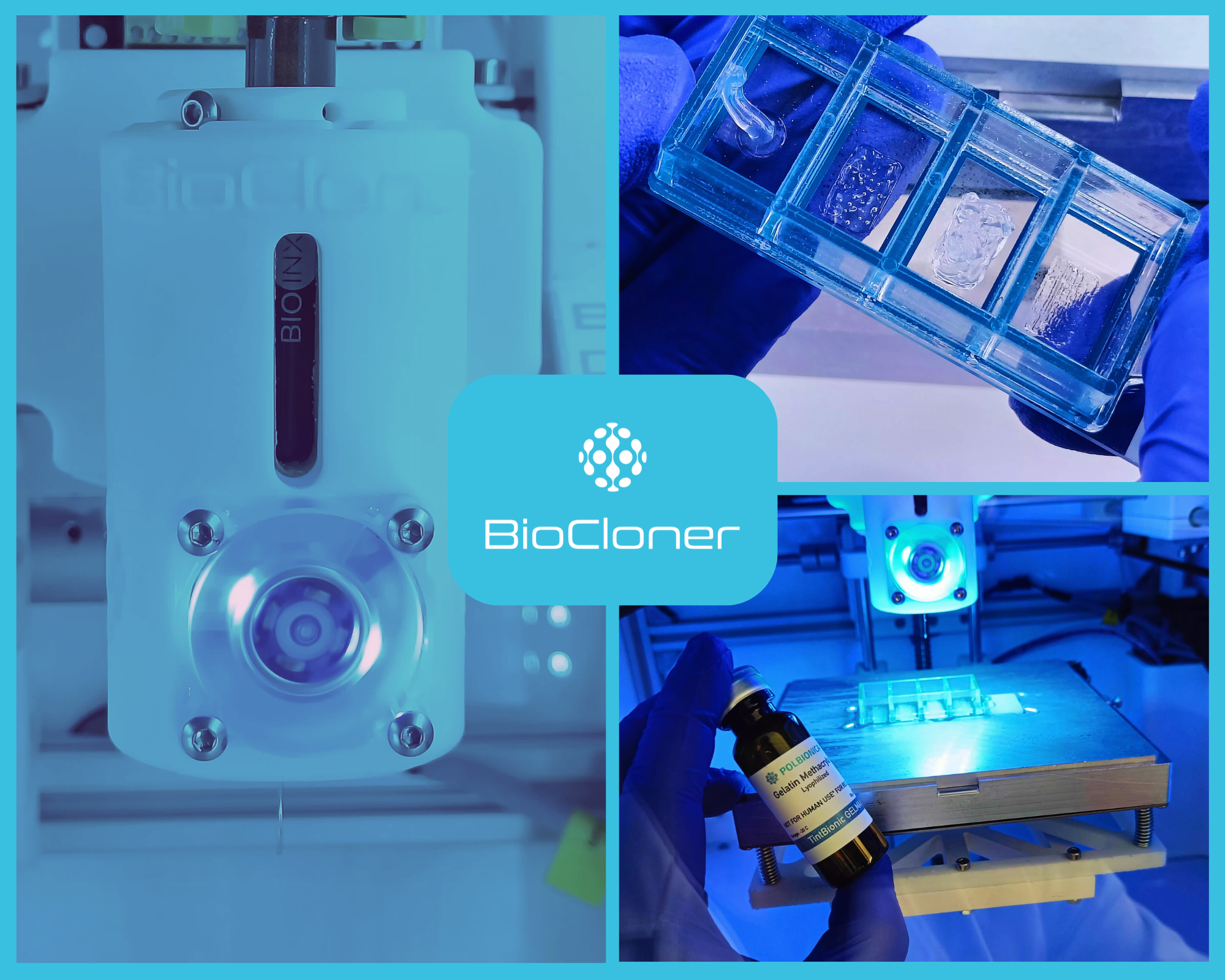

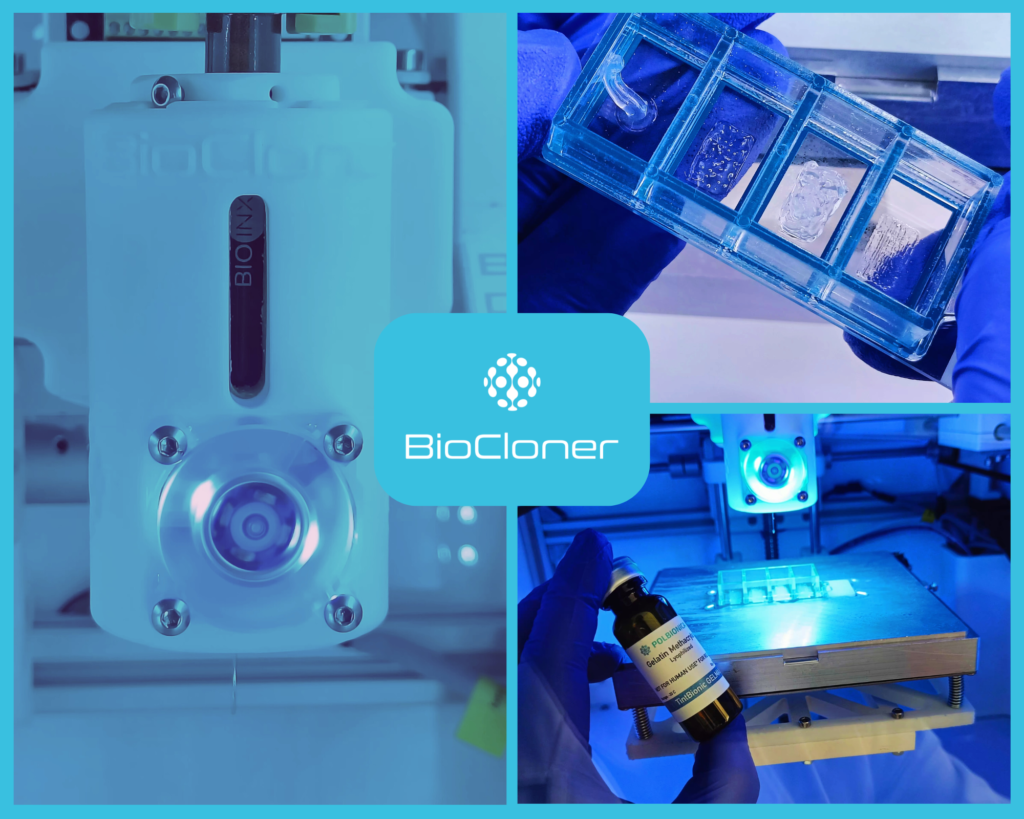

In recent days, we had the opportunity to conduct a series of tests of our prototype 3D bioprinter, the BioCloner Desktop, at the E. J. Brzeziński Biomedical Engineering Laboratory at the Warsaw University of Technology (Faculty of Mechanical Engineering and Technology). The work was carried out under high-cleanliness conditions in a laminar flow cabinet. We had the chance to work with biomaterials provided by BIO INX® – EASYGEL INX© and Polbionica – methacrylated gelatin TINTBIONICTM GELMA80 LAP, which we previously lyophilized to obtain a hydrogel.

Both of these materials are UV-curable, which allowed us to test our dedicated solutions for working with such biomaterials. To fabricate the scaffolds, we used our proprietary printhead, which enabled the process to be carried out with controlled temperature of the extruded material and continuous or spot UV exposure. Constant monitoring of working conditions and process parameters allowed us to produce pre-designed scaffolds, which were later used by researchers at the Warsaw University of Technology for cell seeding. Work with cell cultures within the printed scaffold structures was made possible by adapting the 3D bioprinting protocol to standardized laboratory equipment. Each print was carried out within the volume of a single microscope slide well, measuring 0.5 cm x 1.5 cm.

It was an incredibly productive time, both scientifically and from a business perspective. The outcome was the development of protocols for working with commercial materials based on methacrylated gelatin enriched with photoinitiators. This approach fits perfectly with our product philosophy, as we aim to deliver a bioprinter that can seamlessly operate with both custom-prepared biomaterials and those already available on the market.

The tests provided us with valuable insights into setting the correct parameters for working with the aforementioned materials. These results will be used to develop predefined protocols embedded within our machine.

We are aware that there are still many tests and work ahead of us. Both our solutions and the team are constantly evolving and working to adapt to industry requirements. Soon, there will be more tests, more biomaterials, and inspiring projects from us and our partners.

The BioCloner 3D is racing to the market!

https://youtu.be/RD09RAzseNI