Machining

Precision, quality, innovation

Your trusted partner in engineering

In the era of knowledge-based economy, we put the development of our staff first. We realize that in order to ensure the highest quality of services, it is necessary to raise the qualifications of our engineers. Therefore, we are constantly developing through participation of our team in trainings in the field of CAD / CAM design and programming on CNC machines.

In order to continually increase the effectiveness of our work, we invest in modern infrastructure and machinery. We use high-end Siemens NX software, which offers flexible, highly functional and advanced tools. They provide fast and flawless preparation of manufacturing technology and realistic simulation of parts processing in the 3D kinematics space of the machine tool. All this makes us open not only to standard solutions, but also to more complex and demanding sentences.

We specialize in unit and small-lot production. Our products are used in medical, machine, food and chemical industries.

Our reliability is confirmed by the implemented quality management system in accordance with the international requirements set out in the ISO 9001: 2015 standard. This obliges us to pay even more attention to the quality of our services. If, therefore, you are looking for a business partner who is not afraid to go beyond the framework of standard solutions then write to us and let's start cooperation.

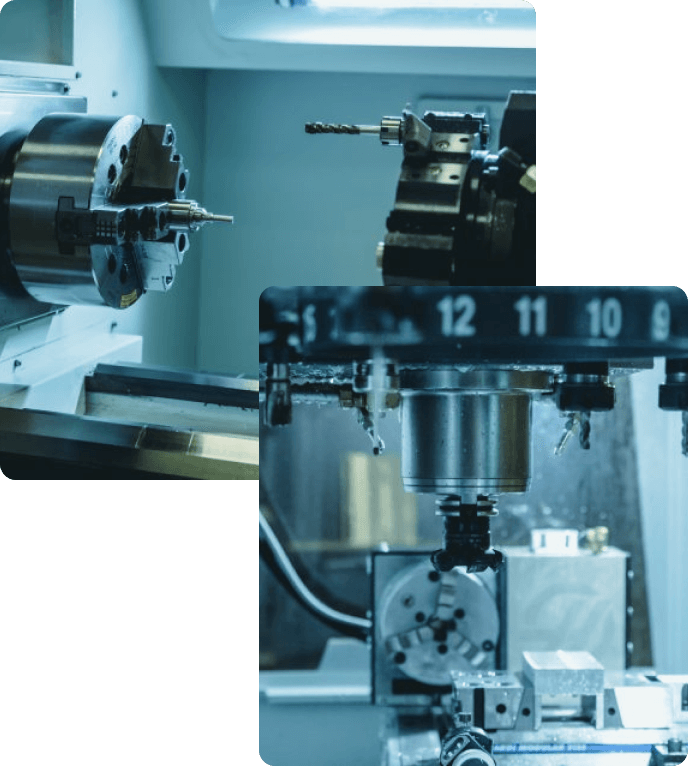

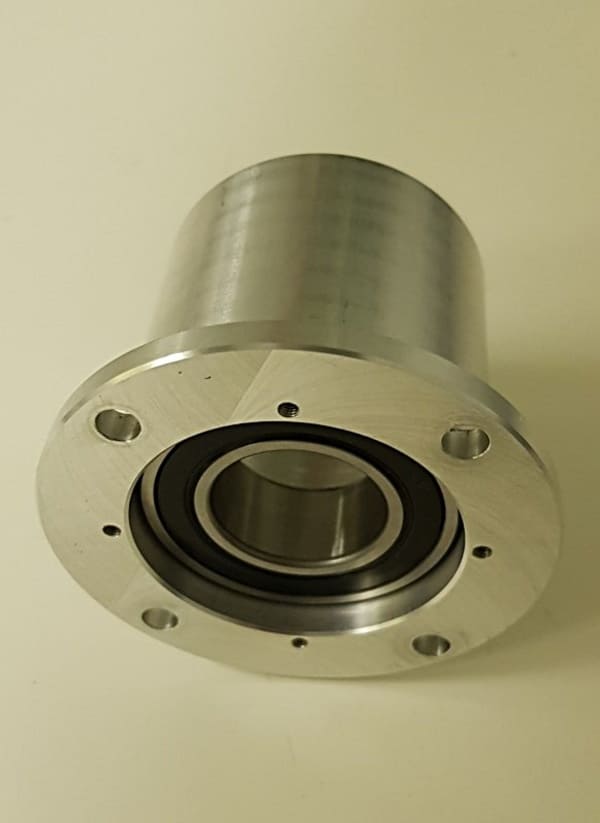

CNC milling

We perform CNC milling using modern, fully automated Haas VF2 4-axis CNC milling machine. Our milling machine maintains the highest precision and repeatability of dimensions and shapes, even during complex technological processes. This ensures that the completed part is fully compliant with the specified requirements. The Haas VF2 CNC milling machine allows us to realize both simple mass-produced elements, as well as complex details of non-ferrous metals, stainless steel and plastics.

Technical data:

• Working area: X: 756 mm Y: 406 mm with: 508 mm

• 4 Rotary axis - maximum diameter: 250 mm

• processing of planes on the vacuum table

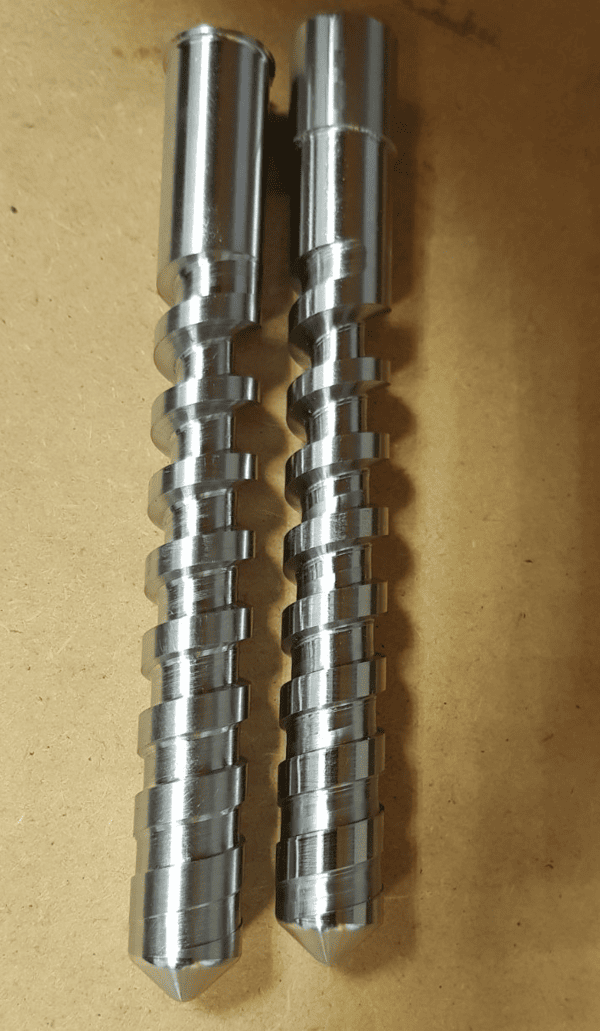

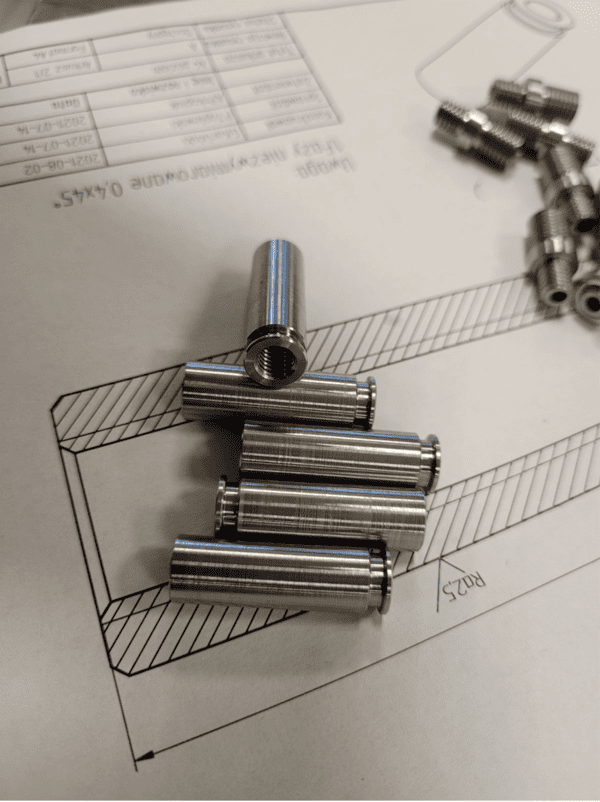

CNC turning

We perform CNC turning using a modern, automated 2-axis CNC TK-360/750 lathe. The lathe gives the possibility of machining cylindrical, conical as well as arched surfaces. The device allows machining of metals (except graphite and cast iron) including non-ferrous metals (aluminum, brass, bronze, etc.), stainless steel and plastics. The machine allows performing such operations as longitudinal and transverse turning, drilling, reaming, threading, cutting.

Technical data:

• Maximum diameter of the workpiece: 210 mm

• Maximum detail length: 700 mm

• Maximum weight of the detail: 40 kg without support and 200kg with support

-

High quality of services

-

Knowledge and experience

-

Individual approach and case analysis

-

Cooperation with the client

Information brochure

Download the brochure and learn about our services supporting the development of your business.

Download the brochure