Created for experts from the world of science and industry.

Contact us

Make

an appointment

Make

an appointment for presentation

lub

Order

a printer

Borrow

a printer

Make an appointment

Order a printer

Complete the form and we will contact you to complete your printer order. Provide your contact details.

Borrow a printer

Complete the form and we will contact you to complete your printer order. Provide your contact details.

Thank you for sending your message

We will contact you soon to arrange all the details of the meeting. We look forward to working together and see you soon!

3D bioprinting is our passion

Today

we are changing tomorrow!

We try to see more. This allows us to better understand the needs of the scientific and industrial communities. Thanks to our research today, we believe that in the future we will change the face of modern technology and medicine.

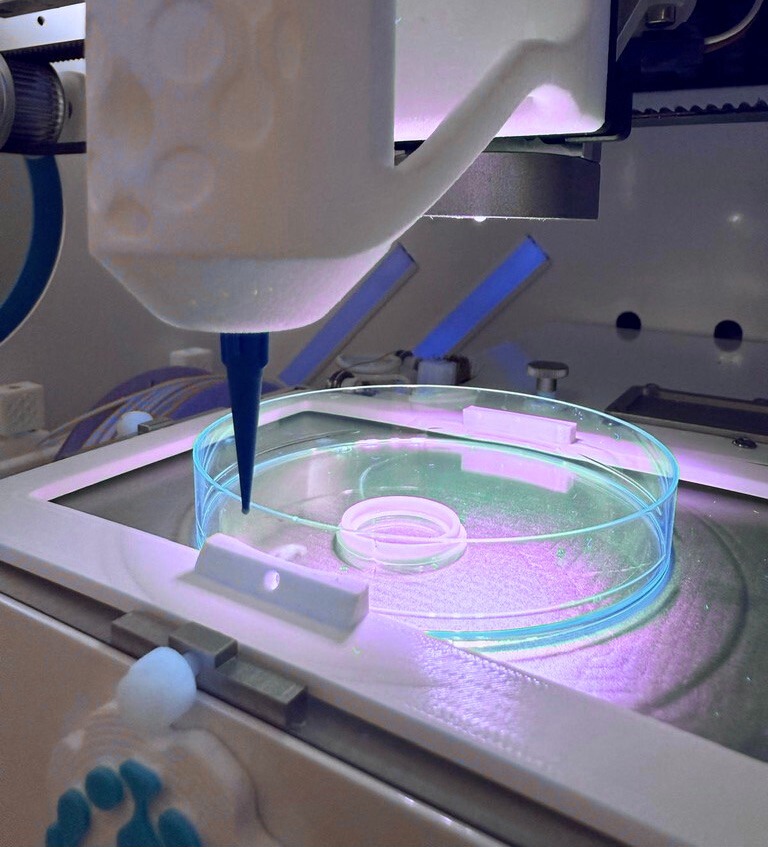

A perfect example of the changes taking place today is the use of 3D bioprinted in vitro models to reduce animal testing. We are constantly developing the technological solutions we have developed, which opens the door to new opportunities in the world of science. We actively strive for a future where our innovative vision supports experts in their daily work to shape a better tomorrow together with them.

About us

INNOVATION IS AT YOUR FINGERTIPS

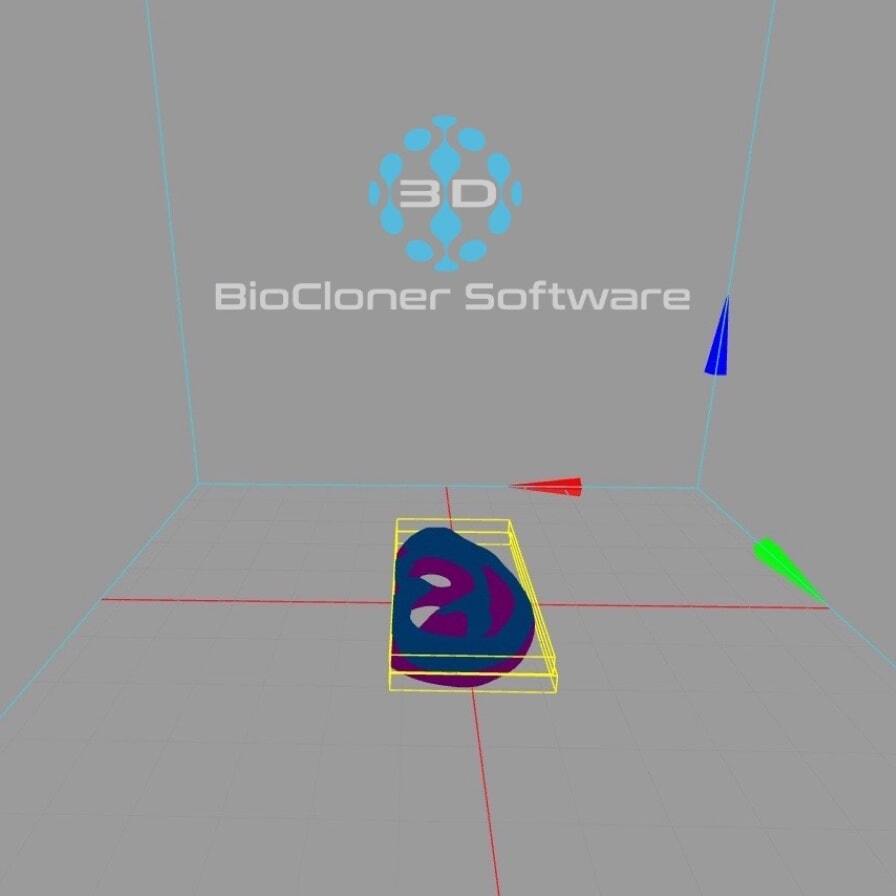

BioCloner Software 3D

The software we created consists of several modules enabling work with a 3D bioprinter at various stages - from protocol design to production of the finished product.

01 User-friendly

BioCloner Desktop was created with the user in mind, ensuring ease of use and, above all, intuitive use. Thanks to the structured and clear interface, using our software is pleasant and effective.

With the ability to choose between Basic, Advanced and Expert modes, you can easily adapt the software to your needs. At each stage of the process, the user is accompanied by messages and warnings so that he can easily achieve the desired final print result.

02 Functionality

Our dedicated bioprinting platform allows the user to load three-dimensional models, as well as perform basic operations such as scaling, rotating, moving and more advanced ones - division into ranges and merging.

By assigning specific heads to appropriate models, you can precisely control the printing process in real time. Using the possibility of generating a mesh of injections allows you to print the entire model in a single session.

03 User Interface

The user interface of our software is delivered directly from the server, which ensures that every printer user who connects to the device always uses the latest version of the software. All improvements and updates are immediately available to users, eliminating the need for manual updates and ensuring the highest quality and safe use.

04 Protocol

Generating a detailed printing protocol enables parameter analysis, ensuring print repeatability and facilitating change control. This is crucial for the stability and precision of creating complex structures, ensuring users can effectively monitor the entire process.

We change for you

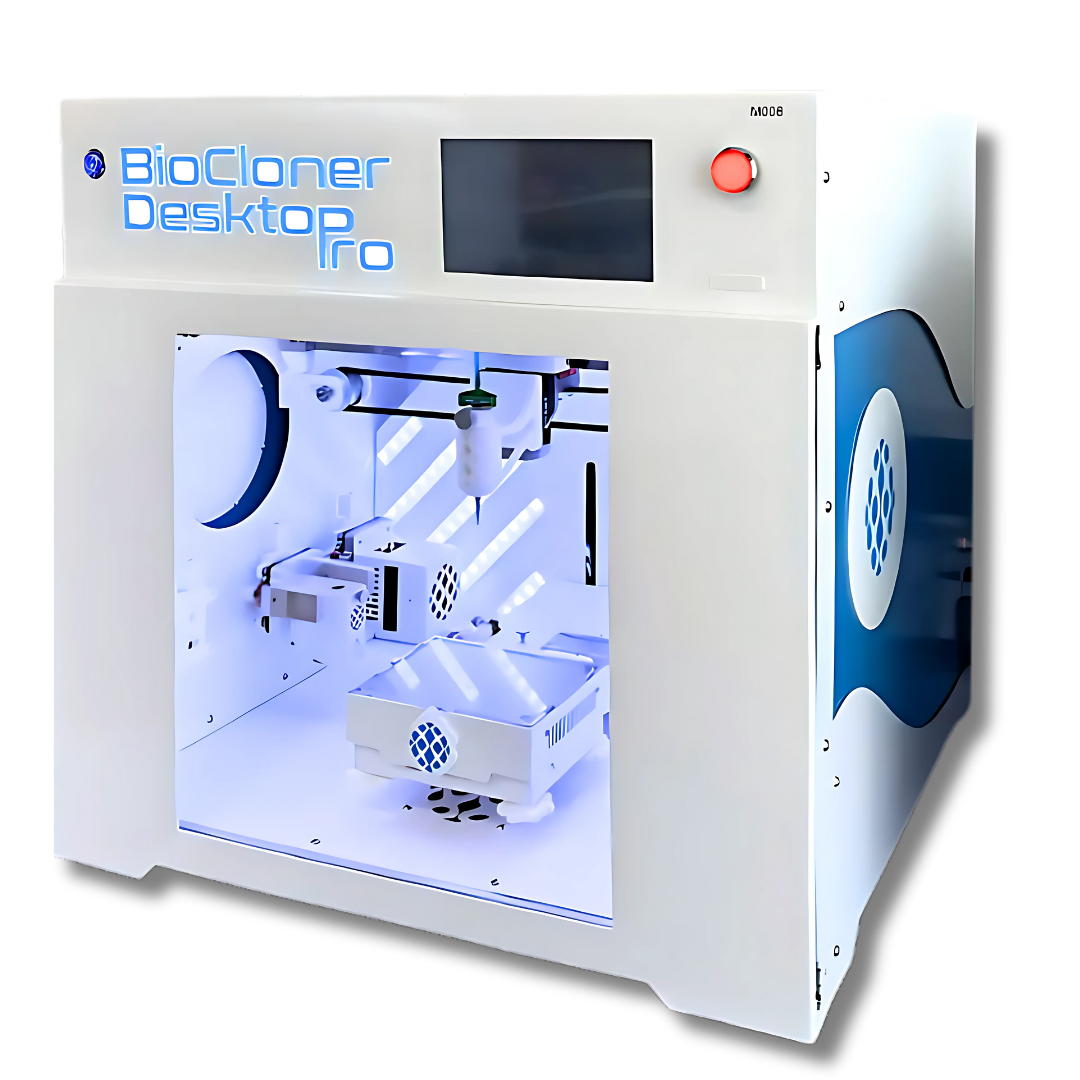

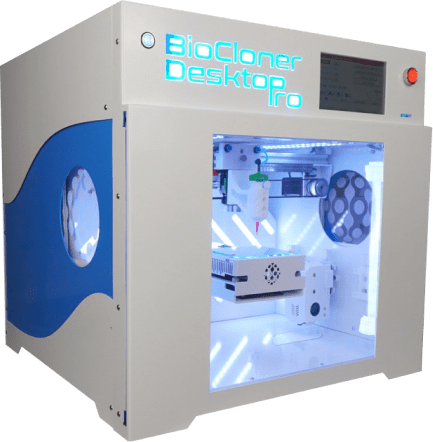

BioCloner Desktop Pro

A set of bioprinters designed in Poland supporting modern medicine and technology.

Click on the selected item,

to go to details

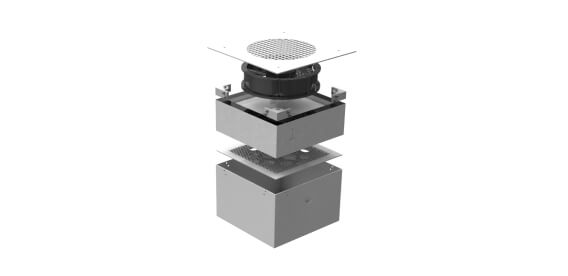

Get to know the individual components

Destop Pro bioprinters

-

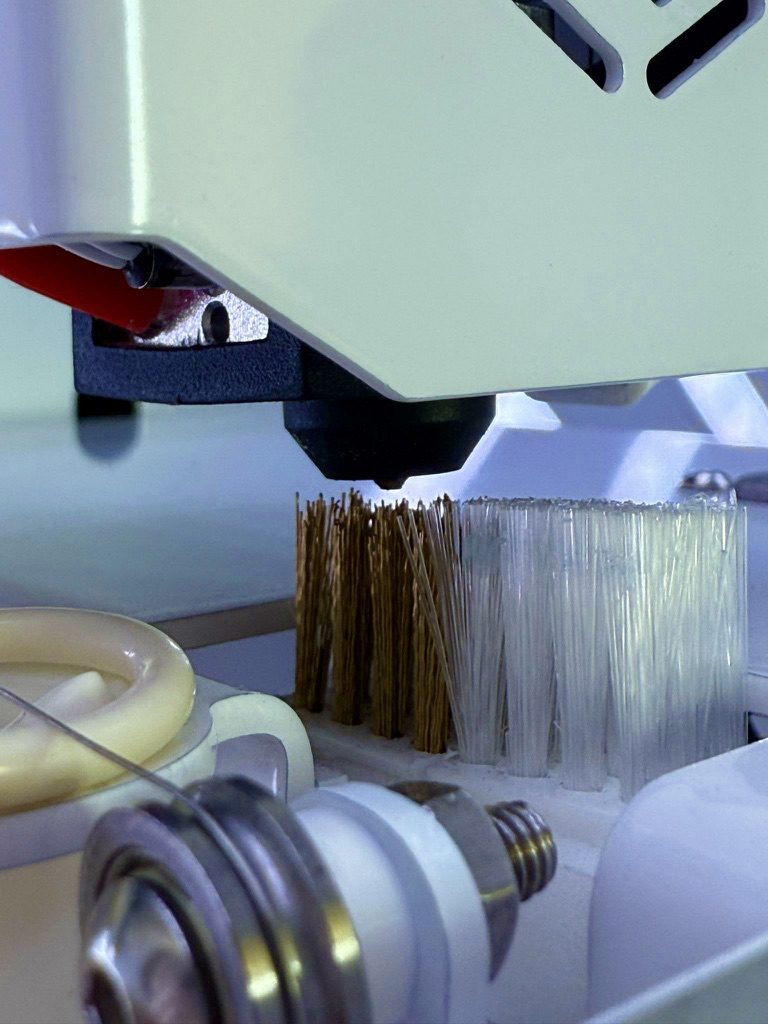

Replaceable print head

-

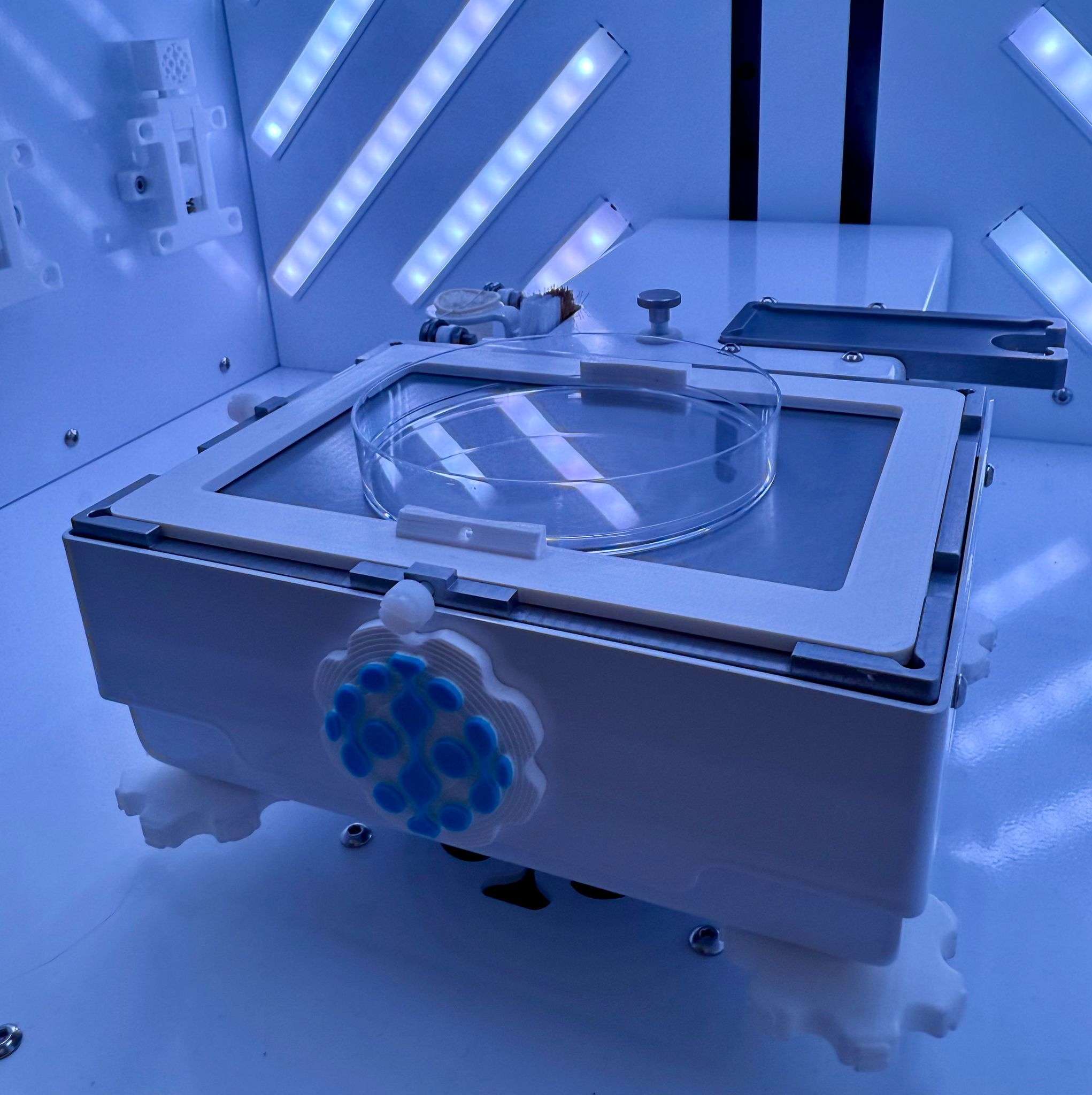

Work table with heating and cooling function

-

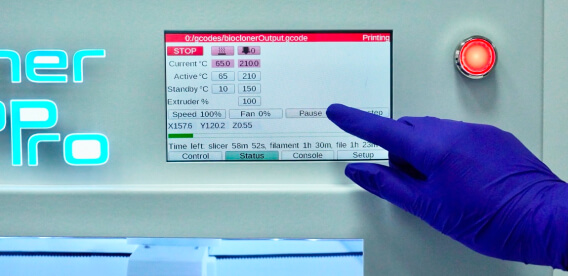

Touch screen and intuitive control

-

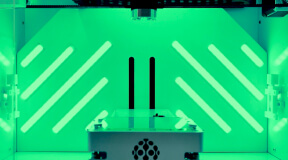

UV-C lamp

-

Configurable tool magazine

-

Hepa filter

-

Configurable space

-

Communication with the user

-

UV on the gantry

Why BioCloner?

-

Intuitive operation

Using our bioprinters, you will be able to quickly and simply prove your hypotheses and test the functionality of newly discovered methods.

-

Universal use

BioCloner provides flexibility for a variety of bioprinting applications, allowing you to work with a wide range of materials and techniques, making it an ideal tool for a variety of research and clinical projects.

-

Simple integration

BioCloner's easy integration with existing laboratory systems and scientific software allows it to be seamlessly incorporated into your research environment, increasing work efficiency.

-

Full control

BioCloner offers advanced control options that enable precise manipulation of bioprinting processes, ensuring high quality and consistency of results.

-

Calibration system

Our dedicated calibration system ensures the reliability and accuracy of each print, minimizing errors and increasing the repeatability of experiments.

-

Specialist Support

We offer comprehensive support from our specialists, including technical assistance, application consulting, and training to maximize efficiency and effectiveness when working with BioCloner

Your partner

in their daily work

BioCloner is your reliable partner in everyday research and clinical work.

With our innovative bioprinting solutions, you can focus on achieving breakthrough discoveries while we provide the necessary technical and expert support.

Check out how BioCloner can make your projects easier!

News

-

New 3D Printer - “Scientific”: Implementation at the PANS in Chełm

W siedzibie Państwowej Akademii Nauk Stosowanych w Chełmie odbyło się spotkanie z udziałem przedstawicieli BioCloner Health sp. z o.o., JM…

-

Use of BioCloner Desktop Pro: Engineering Thesis

Niedawno, na Wydziale Inżynierii Materiałowej i Ceramiki AGH obroniono pracę inżynierską zrealizowaną z wykorzystaniem biodrukarki 3D BioCloner Desktop Pro

-

A personalized droplet formation device developed by BioCloner Health

W ostatnim czasie zespół BioCloner Health opracował urządzenie przeznaczone do precyzyjnego formowania kropli zawiesin ceramicznych, wykorzystywane w klasycznym drop castingu…